What is LED Driver PCB?

Understanding LED Driver PCBs is crucial for efficient LED lighting. These boards regulate power, ensuring LEDs receive the right current and voltage. Composed of components like ICs, resistors, capacitors, and inductors, they convert power accurately while managing heat. This knowledge is essential for optimal LED performance. So, let’s start with understanding what exactly is an LED driver PCB!

Understanding LED Driver PCB

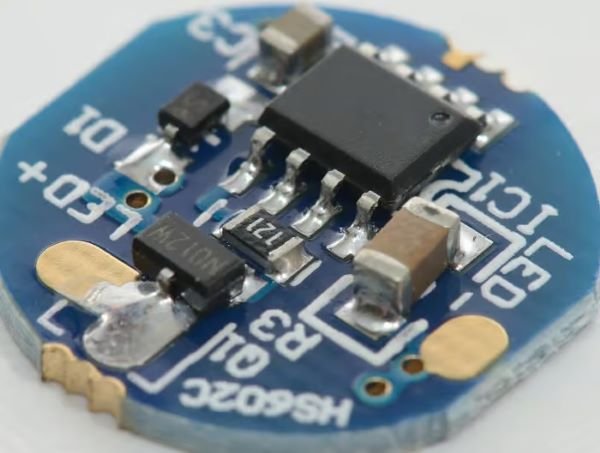

An LED Driver PCB (Printed Circuit Board) is used for regulating the power supplied to LEDs. This specialized PCB ensures that LEDs receive a consistent and appropriate amount of current and voltage, which is critical for preventing damage and ensuring optimal performance. The structure of an LED Driver PCB is designed to support and connect various electrical components that manage power distribution. Typically, it includes integrated circuits (ICs), resistors, capacitors, inductors and sometimes transformers. These components work in unison to convert incoming power to the precise requirements of the LED lighting system. The PCB itself is usually made from a non-conductive substrate material, such as fiberglass, which provides mechanical support while also ensuring effective heat dissipation.

Key Components and Design Considerations

These printed circuit boards are composed of several critical components, each playing an important role in the overall functionality. Among the essential components are resistors, capacitors, inductors and integrated circuits (ICs), each contributing to the regulation and stability of the LED driver.

- Resistors are fundamental in controlling the current flow within the circuit. By providing precise resistance, they help maintain the desired current level to ensure the LEDs operate within safe parameters, thereby preventing damage from excessive current.

- Capacitors are crucial for filtering and storing electrical energy. They stabilize the voltage and smooth out fluctuations, which is particularly important in LED drivers to provide a consistent light output and prevent flickering. Capacitors also aid in reducing electrical noise, improving the overall efficiency of the system.

- Inductors are employed to store energy in a magnetic field when electrical current passes through them. They are vital in power regulation and are often used in conjunction with capacitors to form LC filters, which help in minimizing ripple and noise in the power supply, ensuring a stable current to the LEDs.

- Integrated Circuits (ICs) are the brains of the LED driver PCB, integrating multiple functions into a single chip. These ICs manage the current and voltage regulation, switch the power supply, and provide protection features like over-temperature and over-current protection. They are designed to optimize the performance and longevity of the LED system.

Beyond the individual components, several design considerations are paramount to the performance and reliability of LED driver PCBs. Thermal management is critical, as LEDs generate heat that must be dissipated effectively to prevent overheating and ensure long-term durability. This can be achieved through heat sinks, thermal vias and careful layout design.

Current regulation is another vital design aspect, ensuring that the current supplied to the LEDs remains constant despite variations in input voltage or environmental conditions. This stability is essential for uniform light output and extending the lifespan of the LEDs.

Lastly, attention must be given to voltage requirements. The LED driver PCB must be designed to handle the specific voltage levels required by the LEDs, taking into account factors like forward voltage drop and the total number of LEDs in the circuit. Proper voltage regulation ensures that the LEDs function correctly and efficiently.

Why Do LEDs Need Driver Circuits?

An LED driver circuit is designed to provide a stable current supply to the LED, ensuring it operates within its optimal parameters. The primary function of an LED driver is to regulate the current flowing through the LED. Without this regulation, LEDs are at risk of overcurrent, which can cause excessive heat generation.

- Overheating can significantly degrade the LED’s materials, leading to reduced efficiency, inconsistent brightness and ultimately, premature failure.

In addition to current regulation, LED driver circuits also manage voltage levels. LEDs have specific forward voltage requirements that must be met to emit light effectively. If the voltage applied to an LED exceeds its rating, it can cause immediate damage or reduce the lifespan of the LED. Conversely, insufficient voltage can result in dim lighting or failure to illuminate at all. Therefore, a well-designed LED driver circuit ensures that both current and voltage are maintained within the safe operating range of the LED.

The absence of an LED driver circuit can lead to several adverse effects. Without proper current and voltage regulation, LEDs can exhibit flickering, color shifts and inconsistent brightness. This not only affects the performance and aesthetic quality of the lighting but also reduces the longevity of the LED components. Consequently, incorporating driver circuits is essential for maintaining the reliability and efficiency of LED lighting systems.

Power Source Considerations for LED Drivers

Selecting the right power source is important for LED driver circuits. AC-DC and DC-DC converters each have unique pros and cons that need careful consideration for optimal LED lighting performance.

AC-DC Converters

AC-DC converters are commonly used in LED applications where the power source is derived from the mains electricity supply. These converters are essential for transforming alternating current (AC) into direct current (DC), which is required by LED drivers.

- Benefits of AC-DC converters is their ability to handle a wide input voltage range, making them versatile for various regional power standards.

- However, their efficiency can sometimes be lower compared to DC-DC converters, particularly if high conversion ratios are involved.

- Additionally, AC-DC converters often include power factor correction (PFC) circuits to improve the efficiency and stability of the power supply, thereby reducing energy losses and minimizing electrical noise.

DC-DC Converters

DC-DC converters are used when the power source is already in DC form but requires voltage adjustment to match the LED driver’s specifications. These converters are known for their high efficiency and compact size, making them ideal for applications with limited space. By stepping up or stepping down the input voltage, DC-DC converters ensure that the LED driver operates within its optimal voltage range. However, their dependency on an existing DC power source can be seen as a limitation in scenarios where only AC mains are available.

Driver Architectures

The most common driver architectures include linear drivers, switching regulators and constant current drivers. Each of these architectures has distinct operational mechanisms and use cases, ensuring optimal performance across diverse scenarios.

Linear Drivers

Linear drivers are simple and cost-effective solutions, best suited for low-power applications. They operate by controlling the voltage drop across a series pass element, thereby regulating the current flowing through the LEDs. Linear drivers are known for their straightforward design and ease of integration into compact spaces. However, their efficiency can be compromised by significant power dissipation, making them less ideal for high-power applications.

Switching Regulators

Switching regulators offers higher efficiency by converting input power through inductive or capacitive storage elements. These regulators can step up or step down the input voltage to match the requirements of the LEDs. Common types of switching regulators include buck, boost, and buck-boost converters. Their ability to handle higher power levels and operate with minimal heat generation makes them suitable for a wide range of lighting applications, from residential to industrial settings.

Constant Current Drivers

Constant current drivers are specifically designed to maintain a consistent current flow through LEDs, regardless of fluctuations in input voltage. This ensures uniform brightness and extends the lifespan of the LEDs. Constant current drivers are particularly valuable in applications where precise control over light output is crucial, such as in stage lighting and display systems.

Typical Driver Circuitry

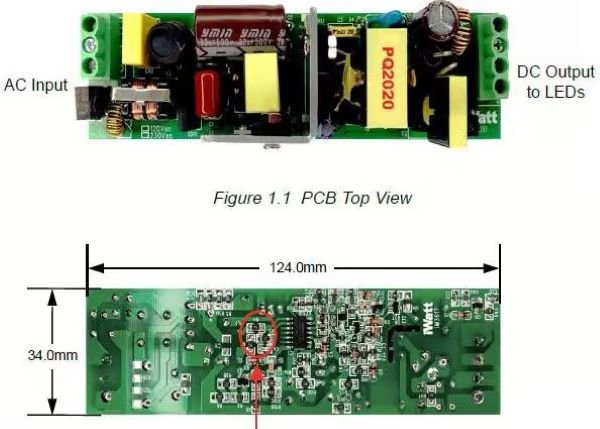

An LED driver PCB tailored for converting a 12V DC input to a 60V LED string output typically comprises distinct stages:

AC/DC Input Stage:

- Incorporates features like fuse and transient protection, rectifier, and smoothing capacitor.

- Includes power good detection for operational status indication.

Intermediate Power Stage:

- Utilizes a buck controller along with MOSFET and inductor for step-down conversion.

- Includes a freewheeling diode for smooth current flow.

Output Stage:

- Integrates components such as current sense resistor, feedback amplifier, and PWM reference generator.

- Incorporates open load detection for safety.

Auxiliary Components:

- Consists of a voltage reference and compensation components.

- Includes diagnostic indicators for monitoring system status.

This PCB efficiently manages a wide DC input range to deliver controlled current output suitable for LED arrays. Its multiple channels enable driving multiple LED strings in parallel, expanding its capacity and versatility.

Conclusion

In summary, LED Driver PCBs are crucial for maintaining the reliability and efficiency of LED lighting systems. They regulate both current and voltage, preventing issues like flickering, overheating, and inconsistent brightness. Choosing the appropriate power source, whether AC-DC or DC-DC converters, and selecting the right driver architecture, such as linear drivers, switching regulators, or constant current drivers, are vital steps. These components and architectures work together to ensure optimal LED performance across various applications, from residential to industrial lighting.